Researchers at a U.S. federal lab have reworked family plastic into a kind of reusable glue that has been described as one of many hardest supplies ever.

Adhesives—supplies that assist issues stick collectively—are generally utilized in on a regular basis life and have a tendency to fall into two classes: sturdy adhesives, which offer sturdy sticking energy however are brittle; and ductile adhesives, which have comparatively weaker sticking energy however are higher capable of take care of stress.

Exterior of nature, this can be very uncommon to discover a materials with the traits of each because the options are typically incompatible.

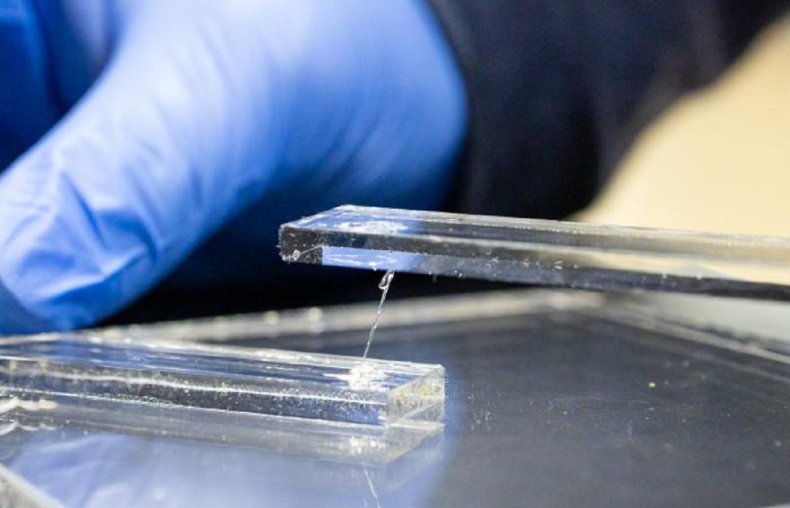

Within the examine, Tomonori Saito, a scientist on the Division of Vitality's Oak Ridge Nationwide Laboratory (ORNL), and colleagues describe how they've produced a fabric with enhanced temperature endurance plus "unprecedented robust adhesion traits" that "surpass these of many current business adhesives."

The scientists' method concerned utilizing a family plastic referred to as SEBS, which is utilized in gadgets akin to handlebar grips, toothbrushes, and sports activities mouth guards. It's simple to make however not engineered for robust adhesion.

The workforce determined to switch the chemical construction of SEBS by utilizing a course of referred to as dynamic crosslinking. This technique concerned combining the SEBS supplies with silica nanoparticles—used to strengthen plastics—utilizing one thing referred to as boronic esters.

The ensuing materials "produces a remarkably sturdy and hard adhesive" in line with the examine, and the researchers assume their work may result in the design of extra robust adhesives that might be used within the automotive, aerospace, and development industries.

"For this examine, we upcycled a commodity thermoplastic elastomer that's generally utilized in every day life," Saito informed Newsweek.

"There are basic challenges in including worth to frequent plastics, to offer them new makes use of past recycling. The principle problem right here is that we're combining what are sometimes opposing properties right into a single materials.

"The adhesive displays high-temperature stability and has very broad service window at -30 to 200 Celsius (-86 to 392 Fahrenheit). In our experiments, the lap shear adhesion on an aluminum floor held round 1350 N for liquid glue and 225 N for dry adhesive, which is equal to 303 kilos and 50 kilos respectively. For the press launch, we used the instance of a sq. centimetre, which, primarily based on our analysis outcomes, can simply maintain 300 kilos."

One other side of the fabric produced is that the crosslinking course of might be reversed, described as "an uncommon function that makes [the materials] engaging for sustainable supplies design."

In line with an ORNL press launch outlining the findings, shear assessments that measure toughness by attempting to detach supplies with drive "had been off the charts" whereas thermal stability was enhanced to 400 levels Fahrenheit. A sq. centimetre of the fabric was additionally capable of maintain "roughly 300 kilos," in line with the lab.

However there have been additionally limitations, akin to that the glue must remedy for one to 2 hours at excessive temperatures of round 400 levels Fahrenheit.

The examine, "Design of robust adhesive from commodity thermoplastics via dynamic crosslinking," was revealed within the journal Science Advances in October, 2021.

Different current scientific research have discovered that the Earth's core is cooling sooner than beforehand thought and that the variety of black holes within the universe might be a mind-boggling 40 quintillion.

Post a Comment