Ready for costs to come back down on new and used automobiles? You may need to attend just a few extra years.

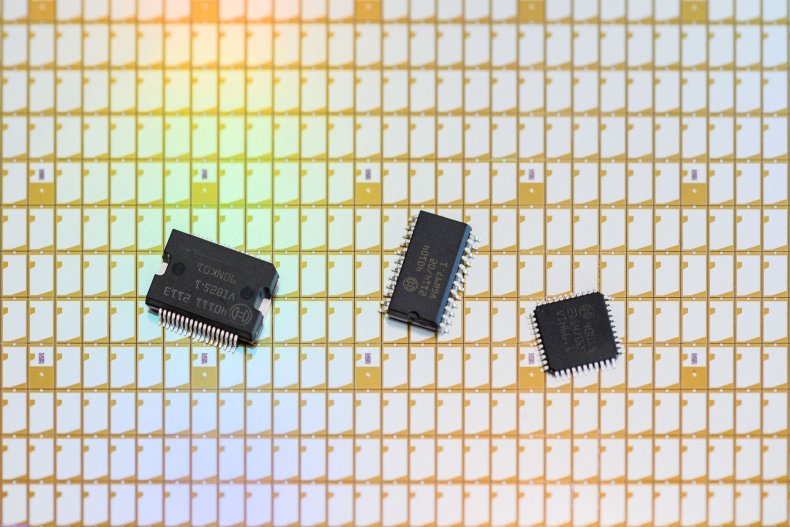

Automotive producers have endured main provide chain disruptions for 2 years now. The shortage of semiconductor chips and different elements, in addition to the worldwide pandemic, has led to manufacturing halts, delays and stock shortages which have roiled the brand new and used automotive markets.

When does it finish? BMW CEO Oliver Zipse not too long ago mentioned that he expects the dearth of chips to stay an issue into 2023. Ford CEO Jim Farley has additionally mentioned not too long ago that the issue will seemingly persist into the following 12 months.

Tom Linton, a senior advisor at McKinsey and Co. and co-author of Stream: How the Finest Provide Chains Thrive, informed Newsweek that many present automotive platforms are a couple of decade previous, which complicates the provision chain by needing to prioritize older tech.

"What occurs is that they find yourself utilizing older applied sciences," he defined. "Semiconductor corporations need to be promoting newer applied sciences. The older nodes are literally tougher to get than the newer stuff, which semiconductor corporations need you to purchase as a result of they earn more money."

Each he and his co-author, Dr. Robert Handfield, a professor of provide chain administration at North Carolina State College, agreed that one of many methods to resolve the issue is with better regionalization of provide chains. However that takes time, with semiconductor amenities taking three years to construct, on common.

Automakers should grapple with the truth that, to be able to execute correct regionalization, they should carry the whole provide chain to their relevant area. Handfield factors to town of Saltillo, Mexico, the place automotive manufacturing vegetation are supported by close by suppliers.

"We have got a free commerce settlement," he mentioned. "Why do not we begin constructing a low-cost nation provide base proper there in Mexico?"

Linton identified that labor prices in Mexico are actually decrease than China's common labor prices.

To Dionis Teshler, CTO of automotive safety firm GuardKnox, the issue will be partly alleviated by software program. If automakers redesign their structure in order that totally different elements can execute a mess of capabilities, then they could defend themselves from the following scarcity.

"You may host options [on the platform] and principally make them items of software program that run on huge hardware platforms," he defined. "Then you'll be able to put it on one other hardware platform and convey them collectively. So even when you're lacking [a semiconductor chip] you'll be able to nonetheless put a bunch of purposes on a unique one."

Adapting to this method may even cut back the typical quantity of chips wanted in a automotive, including additional resiliency to shortages.

Having software-corresponding hardware implies that producers can use various kinds of chips from totally different distributors, opening up extra dynamic types of growth. Teshler says that one of these resolution is just attainable if the automaker is extra forward-thinking about software program than the everyday legacy producer, the place they're open to creating modifications in actual time.

"Not like immediately, the place you principally determine all that in a set method when you design the car," he mentioned. "And that is it. You are caught. You haven't any method of fixing that."

He says that that is the kind of manufacturing that mobile phone makers make use of immediately.

Handfield thinks that situations round provide chains will persist for an additional few years as producers adapt, however cautioned that surprising occasions may proceed to increase that timeline.

"Possibly in a few years we'll have some surpluses in some areas," he mentioned. "However when you've got these main disruptions just like the Russia-Ukraine struggle and the sanctions, these issues additionally take a very long time to work themselves out. They do not work themselves out in a single day."

Post a Comment